Recently, the first domestic 10 kV three-phase coaxial high-temperature AC superconducting cable was laid in Shenzhen, China. This cable is manufactured by ZTT and its laying construction has completed on site. It is the second superconducting demonstration project that ZTT participated in after undertaking the manufacturing and integration of 160kV superconducting DC current limiter, a national key R&D program of China. Yangcheng Evening News reported the project in detail.

Full text is as follows

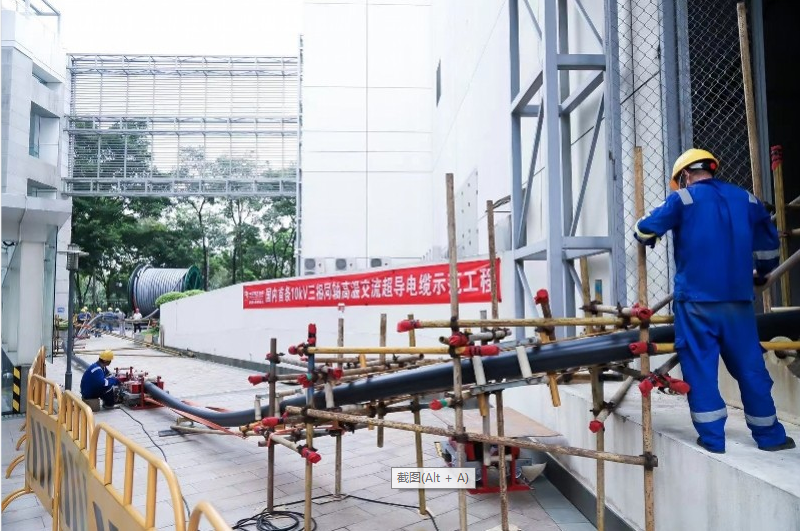

On July 28th, the first 10 kV 400-meter three-phase coaxial high-temperature AC superconducting cable in China was laid completely in Shenzhen in 8 hours, which marked another important progress in the world's first demonstration project of superconducting cable for use in high load density power supply area, and laid a solid foundation for the realization of being put into production within the year.

It is reported that this project is a major science and technology project of China Southern Power Grid Company Limited. The 10 kV superconducting cable developed by Shenzhen Power Supply Bureau of China Southern Power Grid connects 220 kV Binhe Station and 110 kV Xinghe Station in Futian Central District of Shenzhen, and will supply power for important loads such as Shenzhen's landmark, Ping An International Finance Centre. The transmission capacity of superconducting cables is much larger than that of conventional cables. A 10 kV three-phase coaxial high-temperature AC superconducting cable has greater power transmission capacity than a conventional 110 kV cable, and its transmission loss is only 1/4-1/5 of that of conventional cable, which is very suitable for power supply in high load density areas. However, due to the great difficulty in project implementation, at present, the above application scenarios are still blank in China and even in the world.

This superconducting cable runs through busy roads, urban subway areas and core business districts. The laying environment is narrow, and there are special extreme working conditions such as 24.2 meters vertical drop, more than 10 turns less than 90 degrees and short-span S-shaped bends, and high and low transmission pipelines. There is almost no precedent experience to follow. It is a typical complex transmission "small corridor" in big cities, and even laying conventional cables is very challenging.

In order to ensure the successful completion of superconducting cable laying, in the past three months, the superconducting cable project team of Shenzhen Power Supply Bureau of China Southern Power Grid has conducted dozens of field surveys and discussions, and formulated a special research plan of “simulated laying in different places + pre-laying on site”. In Nantong City, Jiangsu Province, a simulation site similar to the demonstration project was built, and various complex extreme working conditions were restored. Many simulation laying drills were carried out, and a large number of valuable data were obtained and abundant field experiences were accumulated. At the demonstration project site, the analog cables of the same scale and weight were used for pre-laying in two times, which provided the most direct reference for formal laying. In the laying process, in addition to the conveyors and winches used in conventional cable laying, the project team also innovatively developed special auxiliary guide, turning radius limit protection, nozzle center positioning, cross-shaped conveying wheel set and other laying tools and instruments to ensure the safe and reliable laying of superconducting cable body. The whole laying was carried out for 8 hours, and there was no damage to the cable body.

Next, the project will enter the stage of installation, test and debugging of superconducting cable accessories, matching cryogenic refrigeration system and measurement and control protection system. When the project is put into production, it will provide a new scheme and a new model for solving the power supply problem in the high load density area of super-large cities globally.